Temperatures across Europe have been on the rise, with the last decade being the warmest on record. In fact, 2020 was the warmest year on record, 1.2°C warmer than the average year in the 19th century.

This has an impact on the working environments of every industry. A new approach to air conditioning is needed in production and manufacturing, where air conditioning is not always a viable option.

Sommaire

The impact of rising temperatures on industrial production

In most factories, temperature control is already a challenge in itself, not to mention the added problem of global warming. This can be due to the heat generated by furnaces and machinery used in manufacturing processes (in steel and plastics production, for example), as well as the intensive, physical work of personnel, such as loading or unloading trucks.

Another factor that is often overlooked is the building itself. Insulation, ventilation and the number of floors in a building will determine how a facility manages the year-round heat generated by modern production methods.

There are many reasons to take temperature control seriously in any factory, production plant or manufacturing facility. Excessive heat not only reduces both production and production quality, it can damage equipment and put employees at risk.

Why are more and more facilities turning to evaporative cooling ?

Evaporative cooling hasn’t been properly recognized until recently. However, companies across Europe are now seeing its great potential in extreme working conditions where standard air conditioning is either too expensive or simply not feasible.

Evaporative cooling units offer major practical and economic advantages for industrial production compared to traditional air conditioning solutions. These advantages include:

Reduce energy costs

According to recent studies conducted among companies in the European Union, energy represents on average between 6% and 9% of production costs in sectors such as basic chemicals, man-made fibers, iron, steel and paper.

Unlike standard air conditioning units, evaporative cooling systems do not rely on refrigerant gases. They can circulate cool airthrough a space and reduce energy consumption by up to 90% by using outside air and harnessing latent heat energy.

Adiabatic cooling makes sense in a context of increasing energy costs (gas, electricity, …) and reducing the carbon footprint in manufacturing processes.

Better productivity

Productivity is likely to deteriorate with each degree above comfortable working conditions. This drop in performance is most common when the work is physical. This drop in performance is most common when the work is physical. Uncomfortable heat not only makes employees feel tired faster, it can also impair their concentration.

Because they do not require a closed environment for maximum efficiency, evaporative cooling units can circulate cool airwhere it is needed most, so they will be able to cool even when doors are open or when workspaces are outside such as truck loading and unloading docks.

Safer working environments

Even in modern work environments, heat-related accidents are common. An industrial production facility can become deadly when temperatures exceed 39°C. The risk of heat stress, exhaustion, heat cramps and heat stroke becomes more dangerous as the body struggles to cool down. This can also decrease your employees attention and motor skills, making it dangerous to operate equipment and machinery.

EU regulations on workplace temperature are tightening, so evaporative coolers are critical to keeping employees safe.

Read also: Indoor air quality, an essential criterion in the industry.

How does it work ?

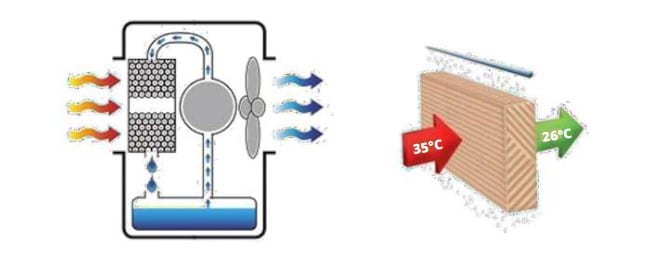

Evaporative cooling units use the natural evaporation process to take warm air from a stuffy atmosphere and turn it into a cool, fresh breeze.

A fan draws warm, dry air through water-filled honeycomb panels.

The physical transformation of water from liquid to gas (vapor) consumes energy. When warm air passes through the humidified honeycomb panels, the water moleculeson the surface evaporate and lower the air temperature.

Please contact our team of experts to learn more about evaporative cooling and its expanding role in industrial production. We can help you choose the best system for your needs.